The demand for demonstrating product sustainability is here for the precast concrete industry.

Many large-scale procurers of construction materials – including some states – now require transparency about the products they consider for projects.

Thus the need to develop an environmental product declaration, or EPD for short.

Some precast producers already have EPDs ready to go, but others are encountering the requirement for the first time when bidding on new projects.

There is no need to wait until the specifier requirement. There is plenty producers can do now to prepare for EPDs.

WHAT IS AN EPD?

EPDs quickly have become the standard for reporting the environmental impacts of construction products.

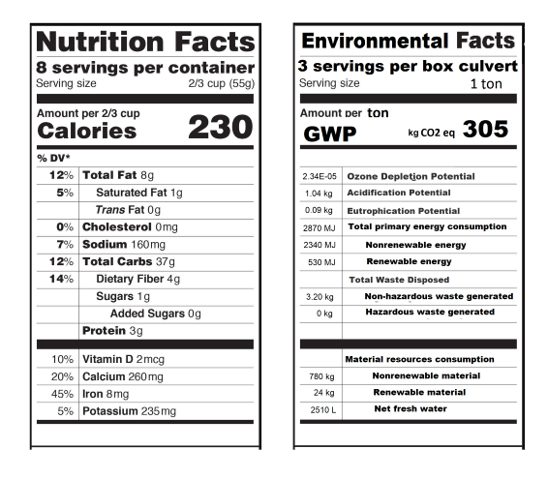

EPDs are similar to nutrition labels in that they summarize environmental information in a standardized way to help consumers make more informed choices about the products they are buying.

The background research used to develop EPDs is called life cycle assessment (LCA). As the name suggests, LCA research considers the life cycle of the product that includes the extraction of raw materials, the processing these materials undergo and transportation across the supply chain to the eventual construction site.

While LCA and EPDs can consider the entire life cycle that includes use, maintenance and end-of-life, EPDs on construction materials typically are limited to the “cradle-to-gate” portion of the life cycle that ends with products at the manufacturer ready for shipment. The global warming potential (GWP) of a cradle-to-gate EPD sometimes is referred to as “embodied carbon.”

WHY DO I NEED EPDS?

As the private and public sectors have progressed in combating climate change, many large-scale procurers of construction materials are now requiring embodied carbon transparency through EPDs.

While several U.S. agencies and companies have long incorporated low-carbon policies into their procurement practices, a major jumpstart arrived in August 2022 when the Inflation Reduction Act became law.

Among other efforts targeted at climate change within the act, it includes billions of dollars in spending for the development of EPDs, the purchasing of low carbon products by the Federal Highway Administration and the General Services Administration along with an unlimited amount allocated to FEMA.

These funds should incentivize industries to increase their familiarity with low carbon procurement methods.

GETTING READY

The increased demand for embodied carbon transparency has led to an emergence of custom software for the concrete industry to produce EPDs. These software solutions seek to ease the pain of what historically has been an expensive and time-consuming exercise typically undertaken by industry associations and larger individual companies.

The data required to generate an EPD reflects the fact that concrete EPDs, and EPDs of structural construction products in general, cover the cradle-to-gate portion of the life cycle, including:

- Raw materials. Extraction of raw materials such as limestone, gravel and other precursor materials as well the production of cement, SCMs (Supplementary Cementitious Materials), admixtures, etc.

- Transportation. Transportation of materials from their production facilities to the concrete producer.

- Product manufacturing. Concrete plant operations up to the point that the product is packaged and ready for shipment.

The three life cycle modules included in EPDs each require specific data.

Raw Materials

EPDs are increasingly required to be supply-chain specific where possible. This means that EPDs from a given supplier will be used when available with industry average data used as a backup when specific data is unavailable.

When preparing EPD data, a producer also provides information for all materials supplied to a given facility. This includes cement and SCM providers, aggregate, admixtures, steel products and other materials specific to a given product line.

To ease the process, EPD software for concrete should include a supplier directory for each company that allows users to enter the relevant information once, then apply these suppliers to a given production facility.

Transportation

Once the supplier directory is completed, the next step is to link suppliers to a given production facility.

To facilitate the transportation portion, provide the distances that materials travel from suppliers to the production facilities and the mode of travel. Note that train and ocean freight cause significantly less environmental impact per mile than trucking.

Product Manufacturing

Concrete plant operations are modeled based on the most recent year of available data. Required data includes total production at the plant as well as the generation of waste and direct emissions.

Energy use at a given facility is gathered in this phase and includes both electricity and fuel use such as natural gas and heating oil. The electricity will then be modeled based on the region-specific grid that is specific to that facility.

GET STARTED NOW

Getting a head start with preparing for EPDs is a good idea given the rapid increase in demand for this information. NPCA members can benefit from the association’s partnership with WAP Sustainability through its software and systems designed to facilitate data collection.

It is important to remember that EPDs cover multiple phases in a product’s life cycle, so data that is required to develop an EPD likely will come from a range of different sources within a given company.

The timeline to produce an EPD can be reduced significantly by organizing data in advance of customer needs. Such an approach allows companies a competitive advantage as both the private and public sectors seek suppliers that are willing to provide them the upstream transparency that they require to meet their own commitments.

James Salazar is the director of sustainability at WAP Sustainability.

WAP Sustainability

NPCA has reached an agreement with WAP Sustainability to partner on assisting NPCA members with obtaining EPDs. WAP Sustainability provides a variety of resources that members can utilize, including information and software. Visit them at WAPSustainability.com.