Family-owned Albuquerque Vault makes big impact in Southwest

Ask Chani Addy-St. Jean about her dad, Mike, and tears start welling in her eyes.

“The hardest working person ever,” Chani said of the owner of Albuquerque Vault Co. in New Mexico. “I stepped in with the intent of him being able to step out a little bit, enjoy life, go play cards. He loves cards.

“But he’s still here every day finding new things to do, finding new equipment, investing in the company. He just never stops.”

It’s that drive that has made Albuquerque Vault, a small family-owned company, a major player in the Southwest.

Mike Addy purchased the company from his father, who established Albuquerque Vault in 1961. The original goal was to supply local and regional cemeteries with precast concrete burial vaults and liners. Septic tanks were added to the product line when other sources of income were needed.

When Mike took over, he recognized the need for diversification and steadily integrated manhole products into the daily production list. The need for a larger facility and more modern shop led to a search for a new location.

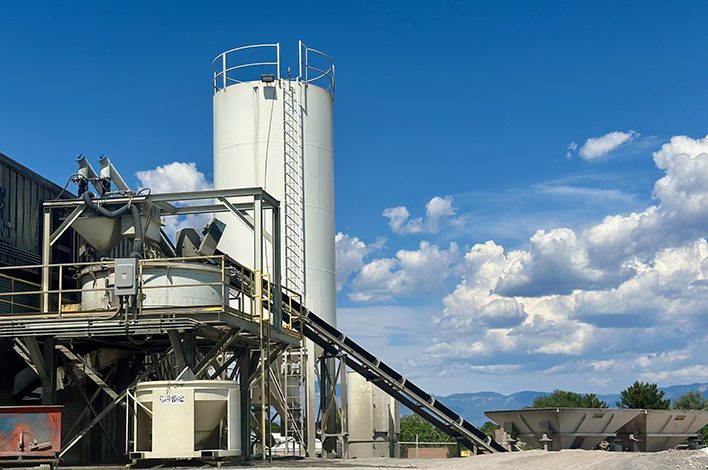

Albuquerque Vault moved to a different part of town, 300 Airport Drive, in 2002. It was a much bigger property with a full manufacturing plant. Mike set the plant up with all of the pieces and tools he knew the company would need to create the same quality products at a much larger scale.

Chani, vice president and engineer at Albuquerque Vault, says business “really just exploded” from there.

“When (Mike) bought the company from my grandpa, it was an established company. It had its roots,” Chani said. “He just keeps doing more and finding new ways to be more successful within the business and take better care of everybody that’s here.”

Mike also transitioned the company’s production work to include more utility products, adding round structures to its offerings in addition to square structures.

“I think that’s kind of what built the foundation of the working relationships that we have with the bigger contractors around here now,” Chani said. “Just being able to provide the service of a full utility material breakdown list as opposed to just a couple boxes.”

YOU CAN COME HOME AGAIN

Chani marks the third generation to lead operations at Albuquerque Vault.

She initially thought she would end up at the family business at some point, but once Chani started her studies in engineering, she wasn’t sure which route she wanted to go. She graduated with a civil engineering degree in 2015 and began working for firms in Arizona and Colorado.

“When I was in college, my intentions were I still wanted to practice engineering within a firm,” Chani said. “But with the goal that I would have the tools to help him on the side or if he needed drawings or paperwork.”

At some point, those intentions evolved, though even Chani isn’t exactly sure what changed her mind. The heavy workload at the firm she was working for played a part. But so did a comment her dad made in passing during a phone call.

Chani had called Mike one evening to tell him she was going to call another firm and see what her options were to move on from her current position.

“He just made a comment in passing on the phone, ‘Oh, well, you could always come back here,’” Chani said. “I was living in Colorado at the time, and I got off the phone and I asked my husband, ‘Is that an option? What do you think?’

“And he was like, ‘Let’s do it.”

Chani and her husband moved to New Mexico, and she returned to working full-time at Albuquerque Vault. It’s a whole different experience working next to her dad.

“When you work with people that are always working harder and trying to do better, it just makes you want to do that,” Chani said. “And though he raised me that way, I did lose sight of that when I was in the engineering firm because it was a ‘here’s what needs to be done, get it done’ kind of mentality.”

She is happy to be back where her dad never stops setting a better example.

“Just coming in here and seeing how hard you can grind to be successful and how even when you feel like you’re doing right, you can still do more,” Chani said. “It’s really cool to be a part of and watch.”

A FAMILY AFFAIR

Being a small, family-owned company hasn’t stopped Albuquerque Vault, an NPCA Producer Member since 2004, from producing in a way that makes the company look a lot bigger on the outside than the staff in the office.

Chani does most of the shop and production drawings and schedules the trucks. Her mom, Brenda Addy, takes care of the accounting, payroll and receivables. Mike has his hands in everything, whatever needs to be done.

Out in the shop, there are nine employees, a couple of whom started about a year ago. But the majority of them have been with Mike since he bought the company from his dad in 1995, moving with him to the new location.

That’s created a really close group that even hangs out together on the weekends … and helps out when household projects need some extra hands.

“This past weekend I was working on a yard project out at my house,” Chani said. “My husband’s deployed, and my dad came out and three of the guys from the shop came out on a Friday and Saturday and shoveled dirt and rocks.

“So, it’s very much a family feel, and everybody kind of looks out for everybody here.”

The closeness of the staff and their longevity with the company is a definite advantage for Albuquerque Vault. Chani said it’s a foundation of their success.

“We have that trust that you are going to be taken care of,” she said. “It’s very much a give and get around here.”

It’s led the shop to be able to run on a four-day work week (Monday-Thursday) since 2009 and still ensure the work gets done.

“I can confidently tell you that if big jobs hit, I can walk out to the shop and tell the guys, ‘Hey, can we make a couple Fridays work? We just need to stay on top of this for these clients,’” Chani said. “And every single one of those guys would show up without a doubt that they’re going to be taken care of and compensated. They’re always there.”

ALWAYS EVOLVING

Mike’s drive for diversification is ongoing. Albuquerque Vault, an NPCA Certified Plant, manufactures and delivers up to 20,000 precast concrete products annually. The company uses self-consolidating concrete (SCC) exclusively, ensuring a minimum 5,000 psi strength with a smooth finish and fewer bug holes. Weekly cylinder break tests are performed in a certified lab, and the company batches its own concrete.

One might think the company’s location in what’s considered a desert area of New Mexico would present challenges to production. But Mike has resolved most of those concerns, ensuring all products are cast indoors in a building that’s temperature controlled and that their admixtures are always on point.

“To be honest, it’s harder on our guys in the winter than in the summer, but it’s a pretty streamlined process at this point,” Chani said. “Usually in the winter, we’ll plan ahead – it’s going to snow this day, it’s supposed to freeze this night. But with it all being temperature controlled in the shop, it’s not a huge, huge change that we make.”

The majority of its production is focused on manholes, followed by septic tanks and grease traps. Albuquerque Vault also produces storm drainage, sand traps, oil sand separators, pump tanks, retaining walls, stepping stones/concrete walls and utility structures.

Chani sees another product leading the charge for the foreseeable future.

“I would guess probably in the next two years, I think the electrical stuff is really going to be what takes off,” she said.

Albuquerque Vault has been a leader in many landmark projects in the Southwest.

Since 2018, Meta, owner of Facebook, has been building nonstop on about 300 acres south of the city. The company has provided various pieces for the development.

Amazon has built warehouses in the region that Albuquerque Vault has done the utility work for.

Netflix is building a huge production studio on the southeast side of Albuquerque that the company is involved in.

And they’ve done the utility work for hundreds of thousands of houses in the subdivisions of a housing development that’s grown exponentially in the past seven years.

“Just seeing it developed from nothing to something functional and knowing that we contributed to all the utilities within that department, that’s incredible,” Chani said.

FOCUSED ON QUALITY

Albuquerque Vault prides itself on the quality of its products and won’t cut corners to save on costs. Each member of the staff ensures products are built to plan and the product is exactly what it needs to be.

“You’re literally going to take it, or we’re going to deliver it, and you’re going to put it in the ground. You’re going to plug and run,” Chani said.

If the company ever sends out a piece that is not perfect in the smallest way, they take ownership of the problem and reproduce it.

“I will get it done right now, and I will get it out to you as soon as possible,” Chani said. “But I am very, very happy to say that it’s very rare that that happens.”

And that high success rate Chani attributes to the staff.

“What we have with the guys out in the shop is we know those guys also understand that we do not settle for anything less than what our standard is,” Chani said. “I think everybody understands that, and that’s why we’ve been so, so lucky and successful in putting out the type of products that we do.”

Albuquerque Vault’s quality products have earned the company work with labs such as Sandia National Labs, White Sands Missle Range and Los Alamos National Labs as well as various departments of transportation. With those types of entities and bigger companies like Meta, the company’s NPCA Plant Certification helps cut through a lot of the hassle in proving Albuquerque Vault’s high standards.

“I can start the conversation with, ‘We do hold our NPCA certification. Here’s our manual. Here’s everything I can provide for you,’” Chani said. “It really gives these other large entities just comfort in knowing that we do produce to a very high standard.”

It’s made Albuquerque Vault a small but mighty force to be reckoned with.

“When you walk in the door, you quickly realize that we are not a big firm company,” Chani said. “We’re just little, and we’re really putting our heart into every piece that comes out of here. And we enjoy it.”