With changing technology come changing ways, even for precasters, who are embracing different ways to get the job done, ultimately speeding up the process from the birth of an idea to the final product.

M-1 Tanks is one of those precasters. The Moses Lake, Washington-based company recently found a new technology that could be incorporated into production, client approval and selling of its precast products.

Cue augmented reality, commonly known as AR.

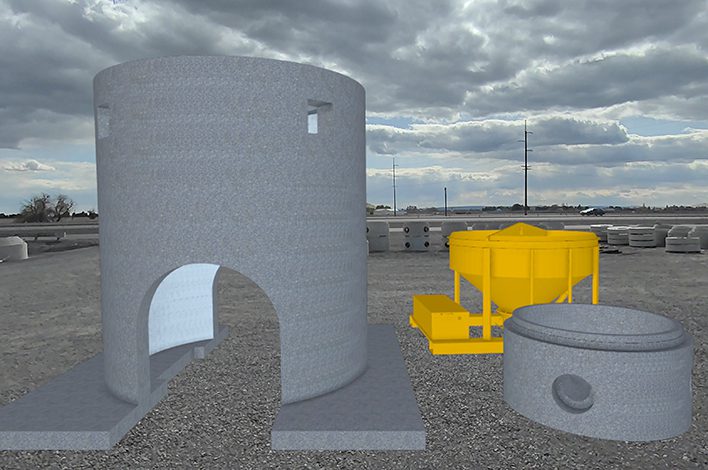

AR is a technology that overlays digital information or virtual objects onto a real-world environment in real-time, creating the opportunity for a speedy production process. M-1 Tanks uses AR to create 3D models of precast concrete structures that can be viewed through a virtual reality (VR) headset. The AR allows customers to walk through and visualize structures before they are built, helping with planning, design and communication once the project begins. AR technology enables users to see joint connections, potential problems and the position of the precast structure that might be difficult to understand from a traditional 2D drawing.

Joshua Wahl, M-1 Tanks’ general manager, was the one who introduced the concept of AR to the company. He was first introduced to AR through SketchUp, a 3D modeling program. The program put one of his working designs into VR and walked him through it. Once he saw that capability, a light bulb went off in his head.

“I got all excited and immediately went out and bought a VR headset, started playing around in the program, and then asked myself, ‘How can I apply this to what (M-1 Tanks) does?’” Wahl said.

Initially, Wahl started doing 3D submittals until he discovered that through the VR headset, you can physically walk through the model.

“It’s a good visualization tool,” Wahl said. “With being able to see and walk through it beforehand, you can spot any problems and map out almost exactly where the production team needs to place something.”

M-1 Tanks placed first in NPCA’s Best Practices Award with its use of AR in its precast concrete designs.

The Best Practices Awards, awarded annually at The Precast Show, recognize industry best practices and improvements that showcase the best way to do a job, treat the environment, save money and more.