When Hurricane Helene damaged a town’s sewage pump station, a precaster 700 miles away came to the rescue.

Lake Lure, a scenic community nestled in the Blue Ridge foothills of North Carolina, is a historic town of about 1,400 residents. It has a reputation for being one of the best mountain getaways in the area and has been the location of several major movies, including “Dirty Dancing” and “The Last of the Mohicans.”

But after Hurricane Helene ripped through the area in late September 2024, the picturesque town became a disaster area. The lake rose above the dam, causing flooding. Landmark bridges were washed out. And the streets and lake were filled with debris from boats, docks, trees and structures.

Boulders slid down the mountain, damaging the town’s sewage system and shearing off the top part of the pump station. Thousands of gallons of untreated sewage emptied into the Rocky Broad River. Lake Lure needed it fixed — and fast.

Brian Houston, P.E., Water/Wastewater Market Leader for LaBella Associates, needed the job completed in four weeks. But local precasters couldn’t promise delivery until early 2025 because of their own recovery efforts..

A mutual client referred precast concrete manufacturer Gainey’s to Houston as a precaster that completed projects quickly and provided quality products. On Oct. 2, Gainey’s received a call for help from Houston.

“I reached out to Brian immediately and told him we were committed to helping him meet his timeline,” said Tim Sander, vice president of operations for Gainey’s, located in Holden, Louisiana. “We’d gone through a disaster like that here, and we empathized with them.”

Over the next few weeks, the Gainey’s team — Sander, estimator Taylor Bordok and project manager Austin Musacchia — determined how they could meet the deadline. Communication with everyone involved was key.

“We had a lot of back and forth with the engineer on what would work on their end versus what we could actually produce,” Bordok said. “We had to find a middle ground.”

Musacchia’s main concern was the timeline.

“It wasn’t just us,” he said. “We were relying on suppliers to get hatches, castings, vent pipes and other items to us in time for us to produce this order when they needed it.”

When the pipe sleeve delivery wasn’t timely, Gainey’s proposed grouting the pipes in place instead, and the suggestion was accepted to keep the project on track.

MEETING THE DEADLINE

Given the tight time constraint, the wet conditions and the logistics of getting concrete workers and equipment to the site, precast was a better solution than cast-in-place concrete. Plus, the existing wet well vault needed some repairs before Gainey’s precast could be put in place.

“We could produce it at our facility and not hinder what they were doing at the job site,” Musacchia said. “This project shows what precast is able to do and the issues we can deal with in a controlled environment.”

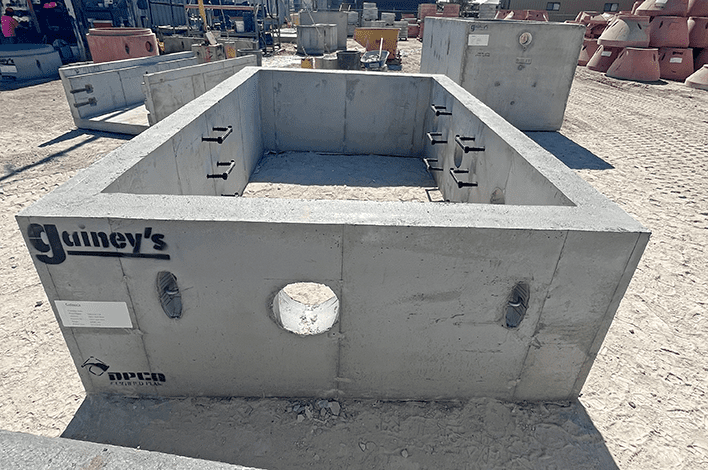

That doesn’t mean it was easy. The custom job consisted of a replacement for the damaged top and walls of the wet well vault plus two risers and a flat top section, in addition to a vault box and a PRV structure.

Gainey’s workers used individual panel pieces so they could adjust the dimensions to fit the existing wet well vault. This piece measures 11 feet, 4 inches by 9 feet, 2 inches by 5 feet.

The vault box measures 9 feet by 6 feet by 6 feet. The PRV structure measures 12 feet, 4 inches by 8 feet, 4 inches by 5 feet. The largest of the three structures Gainey’s produced for Lake Lure, the PRV structure, weighs 20,000 pounds.

Gainey’s used its standard self-consolidating concrete, with a design strength of 4,500 to 5,000 psi.

The main piece had to be poured upside down, then flipped. It was challenging to determine where to place the lifting points so it could be turned over safely, with no injuries to workers or product.

“Under our normal timeframe, this project would have taken two weeks to complete,” Musacchia said. “We put this into production on Monday, Oct. 21, and the last piece was poured on Wednesday, Oct. 23.”

After curing and a quality check, the pieces were loaded on flatbed trucks that Friday.

A BUMP IN THE ROAD

Transportation posed more challenges. One was protecting the precast pieces for the 700-mile journey from Gainey’s to Lake Lure.

“All the shipments were oversized,” Sander said. “We had to get permits through six different states. There was a lot of coordination with the shipping company to ensure we met the regulations for each state.”

Once in transit, Musacchia had to ensure the truck drivers were in constant communication with the job site to help them arrive safely. Many nearby roads were flooded, filled with debris and closed.

Despite the obstacles, the shipments arrived intact at Lake Lure on Monday, Oct. 28, beating the deadline.

A PERFECT FIT

Before the precast pieces arrived, the construction crew repaired the existing part of the wet well.

The big question was: Would the new top fit?

“When the contractor put it in place, there were zero issues,” Houston said. “They just lifted it up and put it on there. The top went on in only one afternoon. We had a very specific thing we had to match, and Gainey’s matched it exactly.”

REWARD FOR A JOB WELL DONE

The story doesn’t end there. On Halloween, the town of Lake Lure discovered Hurricane Helene had destroyed a half mile of sewer on the west side of town, near Chimney Rock Village. This job required building a replacement piece for a damaged vault and creating a new PRV vault. Local precasters couldn’t accommodate the lead time.

Once again, Houston turned to Gainey’s.

“We worked with Gainey’s to figure out the most efficient way to get it from them quickly,” Houston said. “Within a week we had it onsite. If I ever need concrete in a hurry, they’re the guys I’m going to call.”

This was a standard job that used standard molds. The order consisted of a 7-foot-by-7-foot inside diameter catch basin and a 5-foot inside diameter manhole.

This order was delivered on Nov. 28.

Altogether, Gainey’s shipped 90,000 pounds of precast elements to Lake Lure.

Unfortunately, the precast from the second order can’t be installed until the town acquires the property from the property owners. But it is onsite and ready to go as soon as the property issues are resolved.

“In our experience, it takes at least a couple years to get back to normal when a major hurricane makes landfall,” Sander said. “We just wanted to help them get back to some sense of normal as soon as possible.”