Manufacturing specified watertightness in precast concrete products is straightforward if you play by the book

Dutch legend has it that there was once a small boy on his way to school who noticed a slight leak in a dike where the seawater trickled in through a small hole. Knowing that the dike held back the sea from flooding his village, the boy poked his finger into the hole and so stemmed the flow of water. Sometime later a passerby saw the boy and went to get help. Thus the villagers arrived, repaired the dike and sealed the leak.

We all learned this fable as children to teach us an important rule: Do the right thing. But it also taught us an important physics rule: A small trickle of water may soon become a stream, the stream can become a torrent, and a torrent can become the opening for the sea to come in and wash everything and everyone away.

If that dike had been made of quality precast concrete, this legend wouldn’t exist and the boy would have gone to school without fanfare. A good precaster would have known the seawall’s intended use and would have followed industry guidelines to ensure a leak-proof and watertight dike.

Two “P’s” of watertightness

“Watertight” is a term we often hear in describing many precast products. Whether above-ground or underground products, in many instances we want to prevent fluid from getting from one side of the concrete wall to the other. In making our structures watertight, there are two areas we’re concerned with: the concrete itself, and joints and penetrations.

Let’s start with the concrete. When discussing watertightness of concrete, we must consider the two P’s: porosity and permeability.

Porosity is the ratio of the volume of openings (or voids) to the total volume of the material. It basically represents the storage capacity of the material. Concrete is inherently porous, although a sealer can be added to the concrete surface to prevent water penetration. It’s practically impossible to make an absolutely nonporous concrete where water won’t penetrate even a fraction of an inch. However, we can control the size and distribution of those pores and limit the penetration. The pores, which are tiny voids, reside in the cementitious paste (see Figure 1) and can be subdivided into two types: gel pores and capillary pores. The gel pores exist in every system and are part of the glue that forms around the aggregate to make concrete what it is. Gel pores are very small and not a real problem.

What we worry about are the capillary pores, larger pores that depend almost entirely on the water-to-cement (w/c) ratio. If too much water is in the mix, an excess will remain after hydration of cement, and that is what forms capillary pores. Depending on their size and distribution, these pores can be interconnected, influencing our second “P” – permeability.

Permeability is the measure of the ease with which fluids can flow through a porous material. Permeability is expressed in terms of speed (in./s or mm/s) as opposed to porosity, which is expressed in volume per volume (cu in./cu in. or mm3/mm3).

Permeability depends on other factors such as aggregate gradation and density. In high-quality concrete, infiltration is very slow, around the order of 3.94×10-11 in. / s (1.00076 x 10-12 m/s). To give you an idea of how slow that is, it would take about 4,800 years for water to breach a 6-in.-thick wall – well beyond the terms of your warranty for sure.

In order to control porosity and reduce permeability to make a “watertight” concrete, it’s important to follow these five “Watertightness Rule Book” prescriptions: low w/c and the use of densifying admixtures; proper cement content; aggregate gradation; quality manufacturing processes; and execution of joints and penetrations.

Watertightness Rule #1:

Use a low w/c ratio mix design

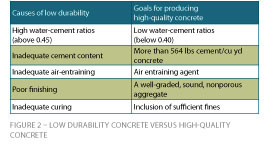

The w/c ratio is the most important factor in concrete design. The water content in a mix controls the moisture’s rate of entry (which may contain aggressive chemicals) and the movement of water during the freeze-thaw process. Compare the leading causes of low durability versus high-quality concrete listed in Figure 2. A mix design for durable, watertight concrete should have a maximum w/c ratio of 0.45 and require a well-graded mixture of fine and coarse aggregates.

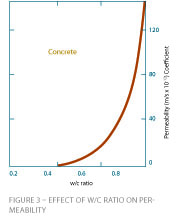

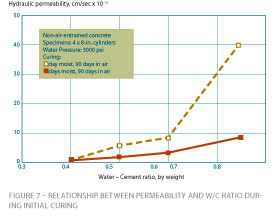

The more excess water in a mix, the lower the strength, durability and watertightness. Excess mix water results in capillary pores – entrapped air pockets in hardened concrete that will reduce its resistance to leakage. On the other hand, too little water can cause placement difficulties and undesirable effects such as honeycombing. The effect w/c ratio has on the watertightness of a concrete mix is illustrated in Figure 3.

Durability and densification can also be improved with admixtures. Many admixtures can be used to improve concrete’s workability, durability and densification. In controlling our water content while trying to maintain workability, water-reducing agents can be used. Air entrainment agents produce near-microscopic independent bubbles that improve the watertight performance of hardened concrete. Air entrainment also improves concrete’s freeze-thaw performance and overall durability in addition to easing the placement process.

Watertightness Rule #2:

Meet minimums for cementitious material

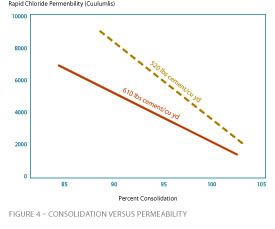

Rich concrete mixes provide a denser, more impermeable and superior finished product. Consequently, specifying that cement content not exceed a minimum amount is recommended. In the case of watertight structures, a minimum cement content of 564 lbs/cu yd is suggested (the effect of cement content on concrete permeability is illustrated in Figure 4).

Cement content or total cementitious content needs to be based on the guiding specifications, but generally cements with a higher fineness (> 600 m²/kg Blaine fineness) will benefit workability and reduce bleeding, both of which are beneficial for watertight concretes.

The use of supplementary cementitious materials such as fly ash, slag and silica fume can also increase concrete’s density, thus reducing capillary porosity and permeability.

Watertightness Rule #3:

Use well-graded aggregates

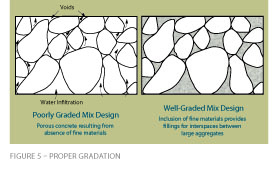

Gradation of the aggregates is a most important factor and should be of primary consideration. Shape and texture of the particles will also affect workability. Aggregate moisture needs to be accounted for when adjusting the mix design so that additional surface water from aggregates does not contribute to a more porous hardened product. Concrete mixtures that are not well-graded can permit water to pass through the finished structure as illustrated in Figure 5.

Rounded coarse aggregates are preferred, if available, as they can be more uniformly placed. Friable1, non-sound aggregates may fracture in the mixing and placement process, compromising their integrity. Fine aggregate (sand) with a higher fineness modulus (> 2.8) is preferred, as it will provide the necessary coarser particles in the mid-range of the combined aggregate structure.

Watertightness Rule #4:

Follow quality manufacturing processes

Quality concrete manufacturing processes are critical to the production of durable, watertight concrete products. Proper attention to important pre-pour activities such as maintaining prescribed mix proportions, form cleanliness, and specified reinforcement placement and minimum cover is very important. For concrete products permanently exposed to earth or moisture, increased concrete cover, as specified in ACI 318, is recommended to ensure the corrosion protection and proper bonding of concrete around the reinforcement. Adequate consolidation of freshly placed concrete is an extremely important factor to produce a high-quality, dense concrete. Added emphasis on consolidation is required for a desirable low w/c ratio concrete, as it requires a higher compactive effort.

The degree of consolidation can have a marked effect on the watertightness of concrete. As illustrated in Figure 4, a 5% reduction in concrete consolidation can result in a 20% reduction in watertightness. This figure also shows that higher cement content improves watertightness. Defect-free surfaces produced by using smooth forms and appropriate release agents can considerably improve the impermeability of a precast concrete product. Concrete must be adequately cured if its optimum properties are to be developed. An adequate supply of moisture, either by covering or other means, is important to ensure full hydration and reduce the porosity level such that the desired durability is attained, as shown in Figure 7. Although a period of moist curing significantly reduces permeability, the effects of curing are less pronounced with lower w/c mixes.

Watertightness Rule #5:

Execute joints and penetrations carefully

A system is only as strong as its weakest link. Close attention to all jointed, connected and sealed areas is absolutely necessary to ensure watertightness. Potential differential settlements and thermal movements must be addressed in the design and manufacture of joints and penetrations.

Construction joints need to be adequately prepared and bonded to ensure a complete contact between two pours.

A well-cleaned and sound surface is very important. In watertight applications, waterstops should be used. In the case of connected surfaces – in a conventional two-piece buried tank, for example – the use of a preformed flexible sealant is recommended. When applying sealant, the concrete surface should be clean and dry. A simple method of determining the cleanliness of a mating surface is to draw a dark-colored cloth across the substrate and note any residue on the cloth. For the penetrations of service lines, seals should be selected that can accommodate any differential movements or settlements.

Little Dutch boy or precaster: Rules matter

Whether you’re building a septic tank in Wisconsin or a dam in Holland, precast concrete products are well-suited for durable, watertight applications. The best strategy for manufacturing a durable, watertight concrete structure is to play by the book and pay close attention to all recommended concrete manufacturing and installation details. Like the legend of the little Dutch boy, the price of ignoring the rules can be enormous.

Claude Goguen, P.E., LEED AP, is NPCA’s director of Technical Services.

1 Friable means easily crumbled or brittle.