Offering design flexibility with rapid installation, precast concrete sandwich wall panels deliver a complete energy-efficient building envelope, including exterior membrane, moisture barrier, insulation and interior finish

By Chris Von Handorf, P.E.

Precast concrete insulated wall panels offer a quick, environmentally friendly alternative to building envelope construction, and with minimal site disturbance.

Standard building construction requires materials to be delivered to a job site, stored and then placed by skilled laborers from multiple trades. Tilt-up wall panels require significant on-site space as well as time for setup and casting, and then need to be rotated onto the building and finished properly to achieve an architecturally desirable exterior.

Conversely, precast concrete insulated wall panels are delivered ‘just-in-time’ and installed, typically by a crew of four to six skilled laborers, directly from the truck onto the building with final finishes already complete.

Insulated precast concrete wall panels have been successfully specified in a plethora of building construction applications. These applications include residential, educational, retail, commercial, governmental (including blast-loaded structures), industrial/warehouse, correctional facilities and more.

So, what is an insulated precast concrete wall panel?

An insulated precast concrete wall panel, or “sandwich” wall panel as it is sometimes called, is a precast concrete wall panel with two layers of concrete separated by a layer of rigid insulation (see Figure 1). The two layers of concrete, often referred to as concrete wythes, are connected by one of many wythe-connecting systems. The concrete wythes can vary in thickness depending on the structural and architectural requirements of a project. Typical concrete wythe thicknesses range from 2.5 in. to 6 in.

Wythe connections affect insulating properties

Several materials are used as wythe connectors. Some of the wythe-connecting systems in use today are plastic pin systems, carbon-fiber truss systems, solid concrete sections and various bent steel-shaped systems.

When selecting a wythe-connecting system, it is important to understand the conductivity of the material being selected. If a highly conductive material is selected, the wythe-connecting system can act as a bridge allowing unwanted heat or cold to pass through the insulation. This will cause the overall R-value of the insulated precast concrete panel to decrease.

It is also important to note that some wythe-connecting systems have been engineered to work with a particular type of insulation. Therefore, verification of compatibility between the selected insulation and wythe connector is necessary.

R-values and insulation materials

The R-value achieved by precast concrete insulated wall panels can vary widely depending on the desired performance of the wall panel. Increased R-values are achieved by increasing the insulation thickness between the two concrete wythes. R-values for insulated wall panels range from R-5 to R-50. The vast majority of the insulating properties come directly from the insulation; however, concrete does possess some insulating properties as well.

Three types of insulation are commonly used in insulated precast concrete wall panel construction. The R-values are approximate and can vary depending on the insulation manufacturer. The common types of insulation in precast insulated wall panels are:

• Expanded polystyrene (EPS), R-value: 3.85/in. to 4.35/ in. (varies with material’s density)

• Extruded polystyrene (XPS), R-value: 5.0/in.

• Polyisocyanurate, R-value: 6.0/in. to 8.0/in.

Based on the R-values above, the polyisocyanurate insulation provides a greater R-value per inch. However, it is important to note that a cost analysis of the three types of insulation may determine that one of the other two insulation types may be more desirable depending on insulation costs in a given area. Additionally, insulation performance in extreme climates should be considered when selecting the insulation type to be used on a given project.

Benefits of precast concrete insulated wall panels

Speed of construction. A precast concrete insulated wall panel system can be used as the complete building envelope, including exterior membrane, moisture barrier, insulation and interior finish. As all of these systems can be installed in one quick process instead of building separate wall elements with multiple trades, the time required to complete the building envelope can be significantly decreased by using insulated precast concrete wall panels.

Also, insulated precast concrete wall panels are fabricated in an off-site manufacturing facility. Wall fabrication is typically nearly complete soon after the first precast panels arrive on site. It is even possible to install the window system in precast panels at the production facility, further decreasing time required to close in a structure. Panels can then be delivered to the job site as needed in order for construction to progress as quickly as possible.

Versatility. Not only can insulated precast concrete wall panels be used to replace multiple exterior insulating and cladding systems, in many structures they can also be used to replace structural elements. Many industrial, educational and correctional facilities have been designed as total-precast structures. In this scenario, insulated precast concrete wall panels can be designed to eliminate both cast-in-place columns

and/or steel columns. In addition to eliminating columns, precast insulated concrete wall panels can also serve as the resisting system for the main seismic force and the main wind force. Eliminating the additional cost of columns and truss systems that are no longer required also makes insulated precast concrete wall panels very attractive from a cost standpoint.

Quality control. The skilled laborers at precast concrete manufacturing facilities perform the same or similar tasks day in and day out with the same tools, under the same controlled conditions. Over time, these workers become very proficient at producing quality concrete products for on-time delivery.

On the other hand, products that are manufactured on site typically have more limited quality control measures in place. These products are also more susceptible to delays and quality issues associated with adverse weather conditions and substandard concrete, as they are typically not produced in a controlled environment.

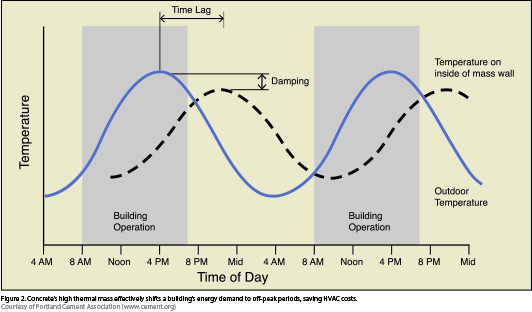

Energy efficiency. Precast concrete has a very high thermal mass when compared with other less-massive materials. Thermal mass is defined as a property that enables materials to absorb, store and later release significant amounts of heat. Concrete’s inherent ability to absorb and store heat and cold can delay and reduce peak HVAC loads. This may allow for initial building cost decreases in the form of a smaller-capacity HVAC system.

Due to the slow release of heat and cold, the thermal mass of concrete can also shift the demand to off-peak time periods when utility rates are lower, thereby decreasing energy costs further (see Figure 2).

The use of wythe connectors with very low heat conductivity, along with the extremely tight building envelope that is created by the use of precast concrete insulated wall panels, creates a very energy-efficient building. Wythe connectors with low heat conductivity will minimize heat transfer from the exterior concrete wythe to the interior concrete wythe and vice versa. Consequently, heat stays inside in the winter and outside in the summer.

Maintenance. An insulated precast concrete wall panel building envelope will require very little maintenance over the life span of the structure. Standard maintenance on this type of construction includes only occasional cleaning as aesthetically desired, and maintenance of the caulking and waterproofing systems. The insulated concrete wall panel system will deliver a service life of more than 75 years.

Fire resistance. Inherently, concrete is extremely fire resistant compared with other materials. As such, insurance costs for a concrete structure are often lower than those incurred when insuring a typical stick-built structure.

The concrete wythes that sandwich the rigid insulation also act as fire protection for the insulation. A typical dry-walled interior finish is flammable and deteriorates quickly when compared with concrete. Once the drywall has deteriorated, the insulation contained within a conventional wall will begin to emit harmful chemicals. The use of insulated precast concrete wall panels will greatly delay the release of these harmful chemicals within the building envelope.

Environmental impact. A recent life cycle assessment (LCA) of exterior cladding products commissioned by the Natural Stone Council and performed by the University of Tennessee’s Center for Clean Products found that “precast concrete and granite exhibit the greatest advantages, although it is unclear which is most environmentally preferable overall.” This study was specifically investigating a two-story load-bearing structure. It is important to note that typical precast concrete cladding is significantly less expensive than granite cladding.

Precast concrete also has the ability to limit the environmental impact of a building project on the building site. As precast concrete insulated wall panels are manufactured off site, and crane-lifted from the delivery truck and installed directly onto the building, the adverse impact that the precast wall panels impose on a site is very minimal. With precast, there is no on-site space required for stored materials, and there is minimal construction debris and less overall site disturbance.

Three design options

Three basic design options can be chosen when specifying an insulated precast concrete wall panel. These options are non-composite panel design, composite panel design and partially composite panel design.

Non-composite panels. When designing a non-composite panel, the two concrete wythes work independently of one another to resist any applied loads. Each concrete wythe will take a portion of the load based on the proportionality of each wythe’s section modulus compared to the other wythe. There is typically a structural or load-bearing concrete wythe and a non-structural or non load-bearing concrete wythe. Any dead loading (gravity loading), such as self-weight or window or louver loading is transferred through the wythe connector to the structural wythe. The non load-bearing wythe is essentially “hanging” from the load-bearing wythe.

Composite panels. In a compositely designed panel, the two concrete wythes work together to resist applied loads. A composite panel of the same thickness will be significantly stronger in flexural strength than a non-composite panel of the same thickness. The wythe connector must be designed to have sufficient shear strength to transfer the horizontal shear between the two concrete wythes. Composite insulated wall panels can typically provide a thinner panel section than a non-composite insulated wall panel. However, the savings in concrete material may be at least partially offset by the additional wythe connector costs associated with making a fully composite panel.

Partially composite panels. Some wythe connector manufacturers will offer a product that is not 100% composite and also a connector that is not completely non-composite; these are partially composite wythe connectors. This is essentially a hybrid between the two extreme design philosophies (composite and non-composite). The wythe connector manufacturers should be consulted for assistance as to which design philosophy applies to their products.

Conclusion

Insulated precast concrete wall panels lend themselves to fast and environmentally friendly construction while remaining virtually maintenance free for years to come. As a building owner, architect or engineer, do not settle for specifying an inferior building system just because it is what you have been doing for years. Set your next project up for success during all phases of the building’s life cycle by choosing insulated precast concrete wall panels and take advantage of this system’s many structural, architectural, environmental, construction and energy-saving benefits.

Chris Von Handorf, P.E., is a technical services engineer with NPCA.