Clarifying the confusion between proof loads and design loads for castings

Much confusion exists in the marketplace about the load-bearing ability of manhole covers and grates. This confusion is understandable and is the result of many different government specifications and industry standards. A summary of the loading of castings and some recommended criteria are listed here.

Brief history of load-bearing criteria as it applies to construction castings

Pre-1940s: The need for cast iron construction castings was met by local foundries. Castings were made from gray iron. Nearly every town had its own foundry, and each foundry had its own designs. Usually the foundries did not complete in-depth loading calculations. Rather, casting design was an educated guess based on trial and error, so adding a safety factor consisted of adding more iron. This is one reason why many old cover designs are so heavy – when in doubt, more material was added.

Post-1940s:

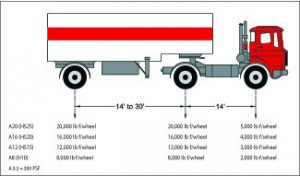

• H-20 Loading: American Association of State Highway Transportation Officials (AASHTO) published its bridge design criteria, commonly known as H-20 or HS-20. It consists of truck axle loading of 32,000 lbs, or wheel loading of 16,000 lbs. This design criteria did NOT specifically address loading on construction castings, but due to casting size, usually only one tire can be on a casting at a time. When contractors ask for H-20 or HS-20 loading, they are asking only for a casting to meet the design criteria of 16,000 lbs. If they do not ask for a safety factor in construction castings, they may not get the quality they are expecting.

• General Services Administration Specification RR-F-621: This specification was put out by the federal government and is the first widespread specification that directly addressed construction castings performance. There are many versions of this specification, such as RR-F-621b or RR-F-621e. This casting has since been renamed the CID (Commercial Item Description) A-A-60005 and is the latest version of this specification.

This specification is important, because it is the first to state that all castings must be able to maintain a 25,000-lb load applied in the center of the casting on a 9-in. by 9-in. pad. The casting is rated as heavy duty if it meets those criteria. There is no direct correlation between the H-20 design load and the 25,000-lb proof load.

• AASHTO M306: This is the newest specification, first published by AASHTO in 1989 and completely revised in 2005. It requires castings to maintain a proof load of 40,000 lbs applied on a 9-in. by 9-in. pad in the center of the casting. This 40,000-lb proof load represents a 2.5 safety factor over the H-20 design load of 16,000 lbs.

• FAA AC: 150/5370-10, item D-751 and FAA AC: 150/5320-6 Appendix 3: These are Federal Aviation Administration guidelines that provide design load criteria for aircraft. This guideline basically states that items must be able to accept a wheel load of 100,000 lbs with a wheel pressure of 250 psi. There is no proof load specification or safety factor specifically mentioned.

What is the difference between design load and proof load?

One common issue that comes up is determining what casting to provide when a loading specification is unclear. It is common for a project to have loading criteria for a manhole frame and cover, and is often just listed on a drawing. Some examples of these loading criteria are: “must maintain H-20 loading” or “must maintain 25 kip loading.” There is no safety factor listed, so it is unclear whether the safety factor must be added by the casting supplier. Most manufacturers assume that when a specific loading is requested, it is a design criterion, so they add a safety factor and identify it as a product that has an appropriate proof load.

The problem with this approach is that the safety factor may have already been incorporated by the engineer into the loading requirement on the drawing, and with the additional supplier safety factor, the product is significantly more expensive than what is actually needed. To clarify, specifying that castings meet ASHTO M306 or “Airport Rated” requirements will ensure the incorporation of a factor of safety, or proof load. Specifying an ASHTO H-20, HS-20 or FAA-compliant casting is a design load and will not include a factor of safety.

The problem with this approach is that the safety factor may have already been incorporated by the engineer into the loading requirement on the drawing, and with the additional supplier safety factor, the product is significantly more expensive than what is actually needed. To clarify, specifying that castings meet ASHTO M306 or “Airport Rated” requirements will ensure the incorporation of a factor of safety, or proof load. Specifying an ASHTO H-20, HS-20 or FAA-compliant casting is a design load and will not include a factor of safety.

Most common loading definitions

• Non Traffic: Due either to the strength or physical characteristics, this casting should not be placed in traffic. This usually refers to decorative items such as tree grates or other items such as beehive grates and ditch grates. The duty rating is 0 to 2,500 lbs, so nothing weighing more than 2,500 lbs should be placed on it.

• Light Duty: This casting may be able to withstand some loading, but it should not be placed in traffic. It can accept loading from 2,500 to 16,000 lbs. An example of this type of product is the meter box, which is usually placed in grassy areas where nothing heavier than a lawn mower will run over it, although meter boxes often end up in driveways and parking lots.

• Medium Duty: This casting can accept loading from 16,000 to 40,000 lbs. As mentioned, above 16,000 lbs is the H-20 design loading criteria. This casting can accept traditional loading, but it does not have the most up-to-date safety factor. Many castings with the medium duty designation have been used safely in traffic areas for years.

• HL-93: This refers to a “live load,” which is described in Article 3.6.1.2 of AASHTO LRFD Bridge Design Specification. The HL-93 live load consists of the design truck (32,000-lb axle, identical to the HS-20 truck of the Standard Specifications) or a design tandem (two 25,000-lb axles spaced 4 ft apart). As a result, castings that meet the AASHTO M306 HS-20 rating meet or exceed this requirement.

• Traffic-Rated: This casting meets the AASHTO M306 proof load, and the loading criterion is 40,000 to 100,000 lbs. This designation is appropriate for traditional traffic loading.

• Airport-Rated: This casting can accept loading from 200,000 lbs and up and includes an additional safety factor beyond FAA design loading.

As confusing as this subject may be, it is important to keep three things in mind:

1. Construction castings are tested using a proof load testing process. It is recommended that castings have a proof load test that is at least twice the expected wheel load.

2. It is important to educate people on the difference between proof loading and design loading.

3. When in doubt, always provide a stronger casting.

Pete DeHaan is district manager, Corporate Accounts with EJ, East Jordan, Mich. (East Jordan Iron Works is now EJ.)

Leave a Reply