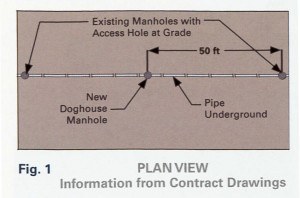

Step 1: At the job site, locate the pipe where the manhole will be installed. Information should be shown on contract drawings. This information should include the location of other pipes in the area (contact local utilities) and surface indicators such as manhole frame and grate, and valve boxes (See Fig. 1). Another option is to use electronic equipment to locate pipes underground.

Step 1: At the job site, locate the pipe where the manhole will be installed. Information should be shown on contract drawings. This information should include the location of other pipes in the area (contact local utilities) and surface indicators such as manhole frame and grate, and valve boxes (See Fig. 1). Another option is to use electronic equipment to locate pipes underground.

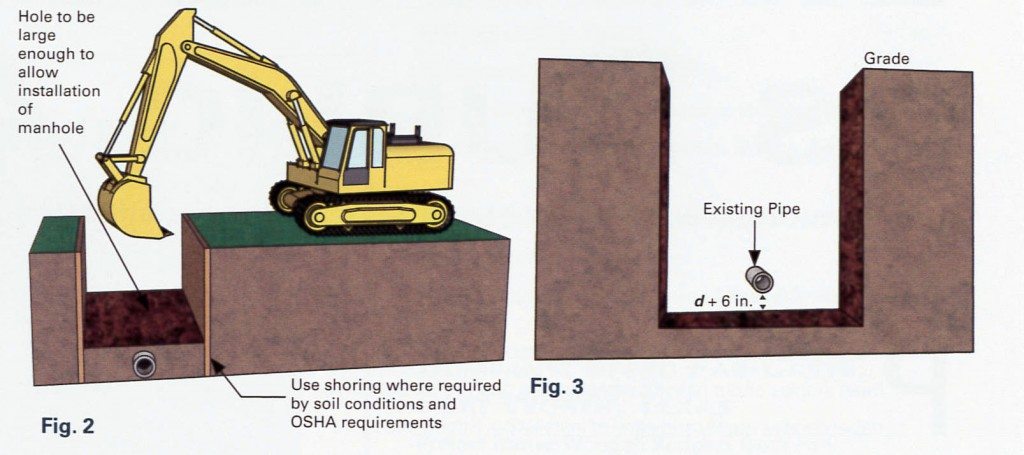

Step 2: Excavate the soil above the pipe. Use shoring to protect the soil from collapsing according to safety regulations. (See Fig. 2)

Step 2: Excavate the soil above the pipe. Use shoring to protect the soil from collapsing according to safety regulations. (See Fig. 2)

Step 3: Continue excavation along each side of the pipe and below, taking care to avoid damaging the pipe. Excavate to a distance of d plus 6 in., where d is based on the type of pipe, type of use and type of supporting blocks used. See Precast Solutions, Winter 2012 issue for derivation of d. (See Fig. 3)

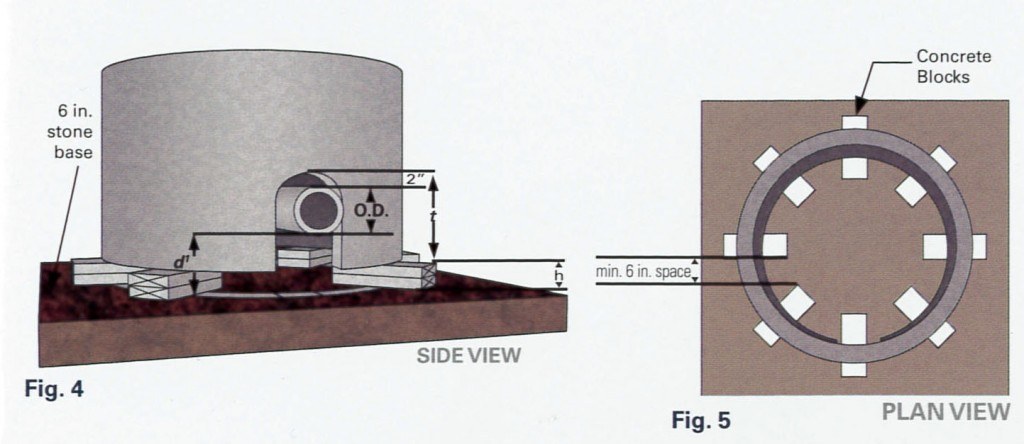

Step 4: Install ¾ in. stone 6 in. thick, and compact it to provide a solid base until the bottom slab is poured. After excavation and compaction are complete, the hole is ready for installation of the doghouse manhole.

Step 5: Use blocks to support the manhole until a permanent bottom slab can be poured. The height of the blocks should be 2 to 5 in. Anything higher than 5 in. can create an unstable condition before the bottom slab concrete is poured; anything lower than 2 in. will interfere with the movement of the concrete under the precast section when the bottom slab concrete is poured.

To determine the height (h) of the blocks, use the formula below.

h = d1 + O.D. + 2 in. – t

Check the distance (d1) from the stone base to the bottom of the existing pipe. Add the outside diameter of the pipe plus 2 in. (see Precast Solutions, Winter 2012). Subtract measurement (t) from the bottom of the manhole to the top of the U-shaped cutout. Fig. 4 shows how it would look after the manhole is installed.

Concrete blocks make excellent support and become an integral part of the bottom slab. The number of supports depends on the strength of the soil and the amount of block surface area exposed to the soil. (See Fig. 5)

Concrete blocks make excellent support and become an integral part of the bottom slab. The number of supports depends on the strength of the soil and the amount of block surface area exposed to the soil. (See Fig. 5)

If the soils are weak, the 6 in. depth of ¾ in. stone will provide a strong base and require a minimal amount of supports. It is important that at least 6 in. of space be maintained between blocks to allow concrete to flow under the precast section and provide a shelf outside; this is necessary to assure that loads from above are distributed over the entire surface of the bottom slab.

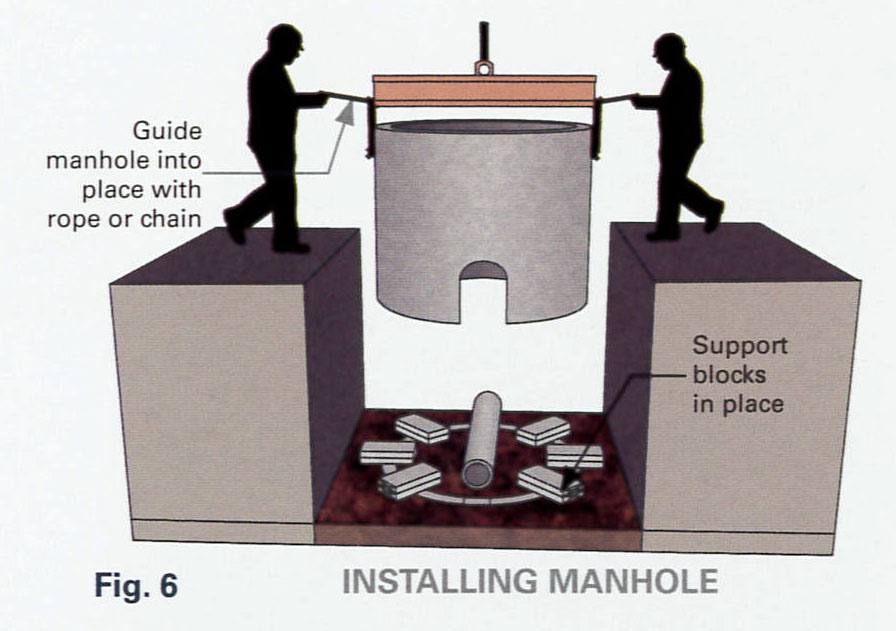

Step 6: After the support blocks are installed, the precast section can be lowered into position. Take care to avoid damaging the existing pipe. Use a rope or chain on each side of the hole to guide the structure into place (see Fig. 6). Do not allow anyone in the excavation until the manhole structure is resting securely on the bottom.

Step 6: After the support blocks are installed, the precast section can be lowered into position. Take care to avoid damaging the existing pipe. Use a rope or chain on each side of the hole to guide the structure into place (see Fig. 6). Do not allow anyone in the excavation until the manhole structure is resting securely on the bottom.

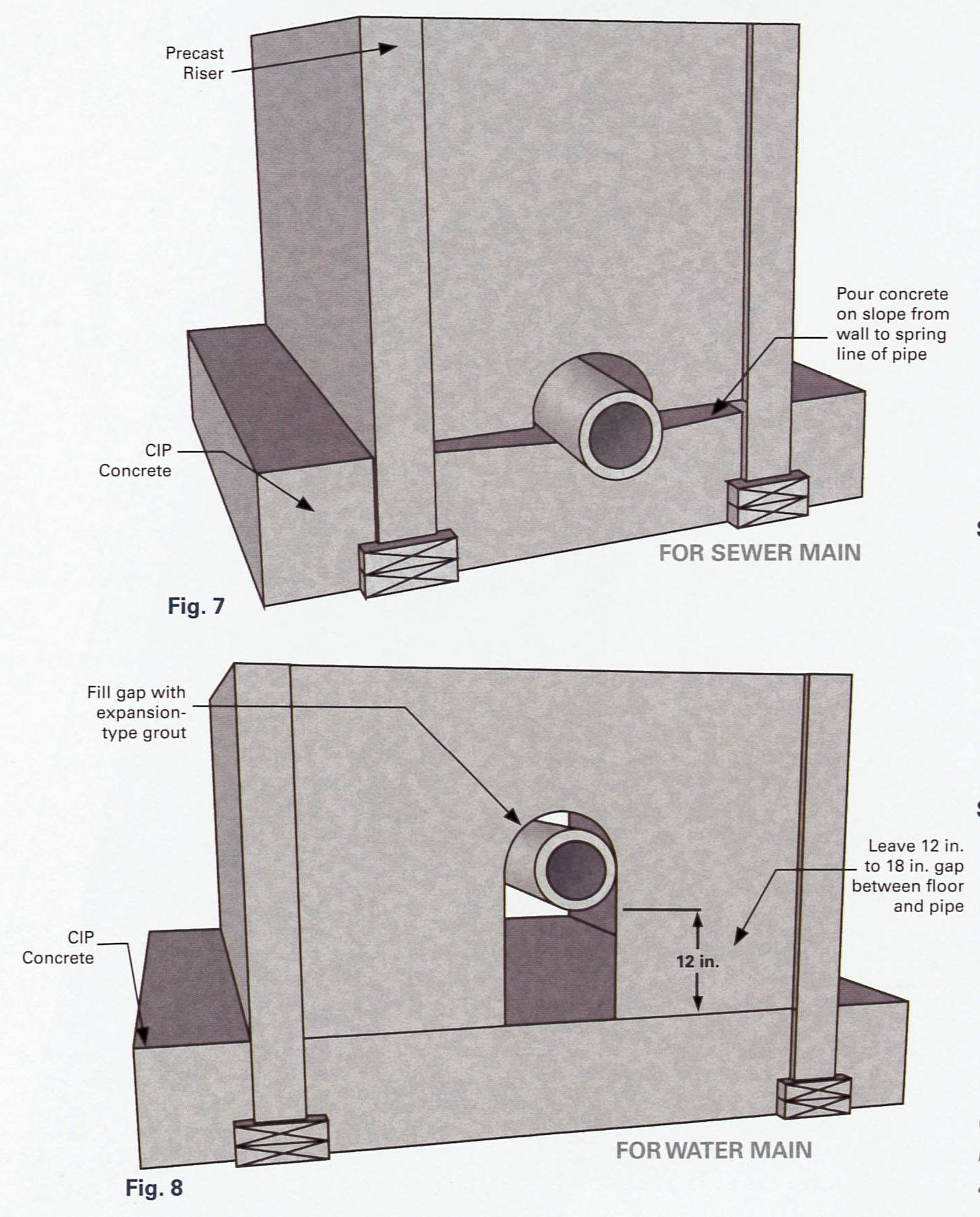

Step 7: In sewer manholes, pour concrete (sloping from wall to pipe to avoid puddling) to form an invert. Use expansion-type mortar to fill the cavity. (See Fig. 7)

In utility boxes, pour concrete to form the bottom slab. Use expansion-type mortar to fill openings. (See Fig. 8)

Gary K. Munkelt, P.E., is a consulting engineer with Gary K. Munkelt & Associates in North Wales, Pa. Contact him at gkm2001@verizon.net.

Leave a Reply