Editor’s Note: This is part two of a three-part series that is intended to educate wastewater structure manufacturers about the nature of septic tank influent, what happens to wastewater in a typical tank and what else can be done to increase that level of treatment. The series also offers suggestions on ways to increase the level of serviceability by offering different types of systems and treatment options for a wider range of needs. Click here for the first article in the series.

Many purchases we make – such as a car, refrigerator or cell phone – force us into a decision dilemma. Do I need seat warmers? How about a “smart” refrigerator or facial recognition for my phone? Septic tanks come with options as well. However, these options can be necessary or even required depending on the region and proximity to sensitive areas. The options may enable additional treatment to increase the performance of the septic tank.

Advanced Treatment

At times, the nature of the wastewater, the sensitivity of the receiving environment, or the unsuitability of the soil or site may require more than just a septic tank and soil treatment system. Your client may need a secondary or advanced treatment system. These systems can treat household waste to substantially lower biological oxygen demand (BOD), total suspended solids (TSS) and reduce specific nutrients or pathogens prior to moving on to the soil treatment system. It’s important to be prepared for these situations, especially if you service an area that traditionally requires secondary or advanced treatment. The examples that follow are a few of the many advanced treatment technologies that exist. These specially designed systems incorporate additional phases to create conditions that facilitate enhanced treatment.

The main types of advanced treatment systems are:

- Aerobic treatment units or advanced treatment units (ATU)

- Media filters

Aerobic treatment units

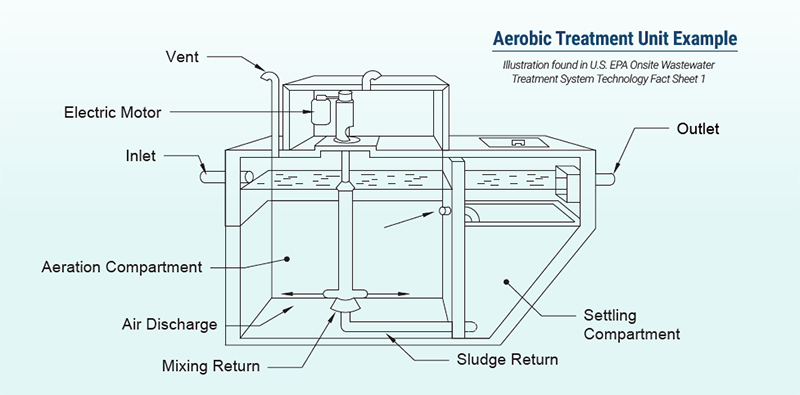

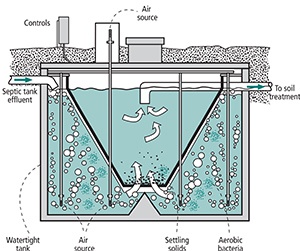

A common type of advanced treatment involves the use of oxygen. ATUs add air to break down organic matter and reduce pathogens and nutrient loading. Conventional septic tank treatment is anaerobic, which means it is done in the absence of oxygen. ATUs use oxygen to foster the growth of bacteria that thrive in oxygen-rich environments. These bacteria break down and digest the wastewater inside the ATU as they are suspended in the liquid. Compared with conventional septic tanks, ATUs break down organic matter more efficiently, achieve quicker decomposition of organic solids and reduce the concentration of pathogens in wastewater. There are many types of ATUs available, and with that comes a variety of efficiencies. According to the University of Minnesota’s Onsite Sewage Treatment Program, a properly operating ATU should produce high-quality effluent with less than 30 milligrams per liter BOD, less than 25 milligrams per liter TSS and less than 10,000 colony-forming units per 100 milliliters of fecal coliform bacteria – an indicator of pathogens and viruses.

What to know when choosing an aerobic treatment unit

There are three basic aerobic treatment unit operation styles: suspended growth, fixed-film reactor and sequencing batch reactor. All three types usually have a septic tank ahead of them that separates large solids.

- Suspended-growth systems include a main compartment called an aeration chamber in which air is mixed with the wastewater. Because most home aerobic units are buried underground, the air must be forced into the aeration chamber by an air blower or a compressor. These systems do not provide media for attachment of bacterial film but rely on bacteria suspended in the wastewater. A second compartment is used for the settlement of solids. The two compartments are connected, so settled bacteria from the settlement chamber can be brought back into the treatment chamber.

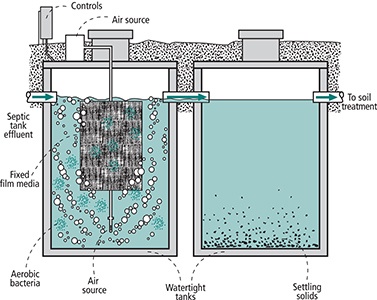

- Fixed-film systems use a porous surface, which provides a medium to support the biomass film that digests the waste material in the wastewater. Designs for fixed-film systems vary widely, but fall into two basic categories. The first is a system where the media is moved relative to the wastewater, alternately immersing the film and exposing it to air. The second system uses a stationary media and varies the wastewater flow, so the film is alternately submerged and exposed to air. In both cases, the biomass must be exposed to both wastewater and air for aerobic digestion to occur. The film itself may be made of any suitable porous material such as formed plastic, fabric, styrofoam or gravel. This would also have a second settlement chamber.

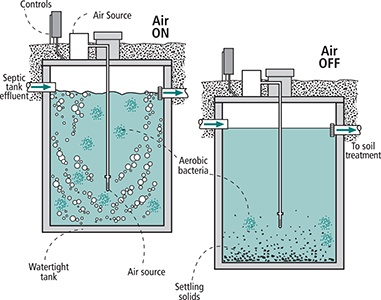

- Sequencing batch reactors contain the aerobic decomposition, settling and return phases in the same chamber. Air is bubbled through the wastewater during the decomposition cycle. The bubbler then shuts off and the wastewater goes through a settling cycle. Once the bubbler turns back on, the tank re-enters the decomposition cycle and the settled bacteria mixes back into the aerobic environment. Next, the treated effluent is discharged to the soil treatment system. These systems are not widely used but can save space.

Media filters

Various media can be used to filter wastewater before sending it to the soil treatment system. Sand is commonly used as a filter media. Effluent from the septic tank flows into a pump tank and is evenly applied over the sand surface. A timer is used to dose the entire surface of the filter intermittently. This draws oxygen from the atmosphere through the sand medium and its attached microbial community. The effluent is treated by physical, chemical and biological processes within the media. Suspended solids are removed by mechanical straining due to enhanced contact and sedimentation. Treatment occurs through the bacteria that colonize in the sand grains. Microorganisms use the organic matter and nutrients in the effluent for growth and reproduction. A properly operating sand filter should produce high-quality effluent with less than 10 milligrams per liter BOD, less than 10 milligrams per liter TSS, and less than 200 colony-forming units per 100 milliliters of fecal coliform bacteria.

Peat is also used as a filter material. The clarified effluent from the septic tank is added by gravity or by pump to the peat filter. The peat acts like a sponge by absorbing and wicking the wastewater and providing treatment as it filters. Peat is partially decomposed organic material with a high-water capacity, large surface area and chemical properties that make it effective in treating wastewater.

In research conducted in Minnesota, peat filters removed high concentrations of nutrients (nitrogen and phosphorus) and produced a high-quality effluent with less than 30 milligrams per liter BOD, less than 25 milligrams per liter TSS, and less than 1,000 colony-forming units per 100 milliliters of fecal coliform bacteria.

A recirculating media filter (RMF) pretreats septic tank effluent by filtering it through a medium of coarse sand gravel, peat or textile before sending it to the soil treatment system. A recirculation system has an advantage in areas where nitrogen contamination is a problem. As wastewater moves through the filter and becomes oxygenated, ammonia is transformed into nitrate. In the recirculation tank, conditions are anoxic (low in dissolved oxygen) and bacteria breaks down nitrates and releases nitrogen back to the atmosphere – a process called denitrification. Because of the large media size, RMFs do not remove fecal coliform as effectively as single-pass sand and peat filters. Liquid effluent moves by gravity to the recirculation tank. Here, effluent that has been recirculated through the filter is mixed with septic tank effluent. Effluent is pumped repeatedly through a lined filter and then back – by gravity or pump – to the recirculation tank. In the filter, biological treatment occurs as the effluent passes the surfaces of the filter media. Treated effluent is collected at the bottom and returned to the recirculating tank where the cycle begins again. After the effluent has gone through the filter several times, a controlling mechanism sends the effluent to the soil for final treatment.

Other materials such as foam, textile, crushed glass and coconut husks are used for filtering media. Some systems let the wastewater filter through the media while others let the effluent trickle over a bed of porous material.

Nitrogen removal

Treatment systems for nitrogen removal are generally done through a sequential process that mimics the natural nitrification/denitrification process using engineered systems. The first step in the sequence uses aerobic processes to transform the organic nitrogen and ammonia products in the septic tank effluent to nitrates and nitrites, which is the nitrification step. A variety of treatment devices can be used to accomplish this aerobic process, such as sand, gravel filters or ATUs.

The second step requires shifting the process from an aerobic to an anaerobic environment. The nitrates and nitrites need to be in an environment without oxygen and with a carbon source, so the oxygen molecules can be stripped off leaving harmless nitrogen gas into the environment. 78% of the air we breathe is nitrogen gas.

There are a variety of systems that are designed to do this, but most rely on this two-step process:

- Aerobic and anaerobic phases

- Introduction of a carbon source during the denitrification step. This is done either by recirculating the nitrified wastewater back through the septic tank – which has high organic carbon content – or by adding an external carbon source to the denitrification unit.

Pathogen reduction

The most common method for final treatment used in on-site systems to remove harmful pathogens is ultraviolet radiation. The germicidal properties of UV irradiation have been recognized for many years. The radiation penetrates the cell wall of the organism and is absorbed by cellular materials, which either prevents replication or causes the death of the cell. The water must be relatively free of turbidity for UV radiation to effectively reach and destroy the organism. Because UV light has a limited distance to be effective, the most disinfection occurs when a thin film of water is exposed for treatment.

Which systems can be used where?

Before rushing out to acquire these advanced treatment systems, it’s important to know which systems are approved in your area. Every state should have a list of approved technologies, so that’s the best place to start. Consider contacting vendors on that list to receive more information on these systems and how compatible they are for your specific products.

Educate yourself

The technology in advanced treatment is moving very quickly and there are many systems that may not be represented in this article. Many NPCA members manufacture and/or sell the systems and can be consulted further on how they may be an asset to your business. The key is to educate yourself on these systems so you can properly explain them to homeowners. Each system comes with maintenance requirements that must be clearly explained to users. Many precasters have developed additional income from the maintenance and service associated with advanced treatment systems.

Claude Goguen, P.E., LEED AP, is NPCA’s director of sustainability and technical education.

Leave a Reply