Trench boxes, shoring, sloping or benching are mandatory for trenches deeper than 5 feet

Editor’s Note: Canadian provinces each have their own Occupational Safety and Health regulations, and precasters in Canada should adhere to their respective laws. However, they generally mirror U.S. OSHA’s regulations, so OSHA regulations are cited here as general guidance for all precasters.

Some people were trying to dig out the workers with their hands,” said a Houston Fire Department officer recently at an excavation site in Texas where one worker suffered serious injuries and a co-worker lost his life when he was buried under tons of soil.1 The young men were working on a drainage system in a 12- to 15 ft-deep, 8-ft-wide trench when the soil surrounding them suddenly collapsed. This is just one example of how proper planning and execution of an excavation/trenching safety plan could have prevented the loss of life.

Excavation and trenching are among the most hazardous construction operations, according to OSHA of the U.S. Department of Labor. Cave-ins pose the greatest risk and are much more likely than other excavation-related accidents to result in worker fatalities.

Despite having the knowledge and means to prevent fatalities, almost 40 workers die in trenching or excavation-related cave-ins in the United States – every year.2 Lack of protective systems is the leading cause of trench-related fatalities, as reported by OSHA inspections; most occurring at depths of less than 10 ft.3 For precasters that do it all, including manufacturing, shipping and even the installation of underground precast concrete products, excavation safety measures should be addressed and implemented to prevent avoidable on-site accidents and injuries. The combination of loss of human life, fines, lawsuits and poor public relations could mean the end of a successful business.

Mandatory preparation saves lives: 12 critical questions

Whether you are shoring, trenching or backfilling, it is vital to approach every job – new projects and customary construction – with the utmost care and preparation. Many on-site accidents result from inadequate planning and execution of an excavation safety plan. Being reactive can ultimately lead to added cost to fix safety problems and can increase the possibility of a cave-in or other excavation failure.

Planning for excavation operations is one of the most important steps in avoiding accidents. Knowing as much as possible about the work site or job and the equipment and materials needed is essential, and important questions must be addressed prior to digging (taken from U.S. OSHA regulations):

1. Have all underground utilities and their estimated locations been accounted for (sewer, telephone, fuel, electric, water lines)? [29 CFR 1926.651(b)]

• Has the exact location of the installation been determined?

• Has the utility or owner been contacted?

2. Is there proper access and egress? [29 CFR 1926.651(c)]

• Structural ramps used for access or egress of employees must be designed by a competent person.

• Structural ramps used for access or egress of equipment must be designed by a competent person qualified in structural design and must be constructed in accordance with the design.

• Safe means of egress must be located in trench excavations that are 4 ft or more in depth so as to require no more than 25 ft of lateral travel for workers.

3. Will there be vehicular traffic exposure near the excavation? [29 CFR 1926.651(d)]

3. Will there be vehicular traffic exposure near the excavation? [29 CFR 1926.651(d)]

Employees exposed to vehicular traffic must be provided with and wear warning vests or other garments made of reflectorized/high-visibility material.

4. Is there proper protection from exposure to falling loads?

[29 CFR 1926.651(e)]

Employees must not be permitted underneath loads handled by lifting or digging equipment.

5. Is there a warning system for mobile equipment?

[29 CFR 1926.651(f)]

If mobile equipment is operating adjacent to the excavation or when the operator’s view is obstructed (does not have a clear and direct view of the edge), a warning system must be used (barricades, hand or mechanical signals, or stop logs).

6. Is there a potential for exposure to hazardous atmospheres?

[29 CFR 1926.651(g)]

• Preventive measures must be taken to prevent exposure to harmful levels of atmospheric contaminants (oxygen deficiency or hazardous substances).

• For exposure with less than 19.5% oxygen, proper respiratory equipment or ventilation in accordance with OSHA standards is required.

• For concentration of flammable gas exceeding 20% of the lower flammable limit of the gas, proper ventilation must be provided.

• Atmospheric conditions must be monitored when controls are used.

• Emergency rescue equipment should be available where hazardous atmospheric conditions exist.

7. Will water/water accumulation be an issue?

[29 CF 1926.651(h)]

• Employees must not work in excavations where there is accumulated water or water is accumulating unless adequate precautions have been taken.

• If precautions are used (diversion, dewatering, special supporting systems or water removal), a competent person should monitor the removal operations.

8. Will the excavation be near existing structures? If so, what is the stability of the adjacent structures?

[29 CFR 1926.651(i)]

Where stability of adjacent structures is endangered by excavation operations, support systems must be provided to ensure stability of such structures for the protection of the employees.

9. What types of soil will be found? [Appendix A to Subpart P- Soil Classification]

• It is necessary to know the characteristics of the soil at the particular job site (type of soil, water content of soil, previously disturbed soil).

• Follow OSHA Appendix A Soil Classification procedures to classify soils.

• Contact your county Soil Conservation Service office for a list of soil scientists in your area, or local geotechnical and/or soils engineers.

10. Is there adequate protection from loose rock or soil? [29 CFR 1926.651(j)]

• Adequate protection must be provided to protect employees from loose rock or soil that could pose a hazard by falling or rolling from an excavation face. Protection can consist of scaling to remove loose material, installation of a protective barricade or other means.

• Materials or equipment must be kept at least 2 ft from the edge of excavations.

11. If a protective system is needed, what type of system is adequate? [29 CFR 1926.652(a)]

Employees in excavations must be protected from cave-ins by adequate protective systems except when:

• Excavations are made in entirely stable rock

• Excavations are less than 5 ft deep and a competent person determines there is no indication of a potential cave-in.

12. If employee exposure to any hazard is anticipated, is there a plan in place to perform daily inspections of excavations, adjacent areas and protective systems?

12. If employee exposure to any hazard is anticipated, is there a plan in place to perform daily inspections of excavations, adjacent areas and protective systems?

[29 CFR 1926.651(k)]

Daily inspections of excavations, adjacent areas and protective systems shall be made by the competent person to ensure a safe working environment.

Each of these questions should be answered during the planning stage of construction, following federal standards. OSHA 29 CFR 1926 Subpart P (OSHA 1926.651) thoroughly addresses each of these points and outlines proper procedures and minimum requirements for excavations. The competent person in charge of the excavation should fully comprehend the requirements laid out in the Specific Excavation Requirements section (OSHA 1926.651).

Design of Protective Systems for Trenches & Excavations

As defined by OSHA, protective systems include one or more of the following designs:

1. Sloping the ground

2. Benching the ground

3. Shoring the trench with supports (planking or hydraulic jacks)

4. Shielding the trench (trench box)

OSHA 1926.652 addresses the requirements for each type of protective system available. The competent person should, once again, read all the requirements laid out in this section and determine the appropriate protective system. The slopes and configurations of sloping and benching systems must be selected and constructed by the employer or designee in accordance with regulations. OSHA 1926.652 requires the following:

• Sloped no steeper than 1.5:1 (34 degrees); or

• Maximum allowable slopes and configurations per Appendix A & B; or

• Designs using other tabulated data; or

• Design by a registered professional engineer

Proper design, construction and placement of support structures will provide a safe work environment for employees. Designs for trench and excavation protective systems must be selected and constructed by the employer or designee. OSHA requires the following:

• 1926.652 Appendix A and Appendix C or Appendix D; or

• Using manufacturer’s tabulated data; or

• Other tabulated data; or

• Design by a registered professional engineer

Things to remember during the job

• Just as outlined in the planning phase, inspections of the excavation, adjacent areas and protective systems need to occur each and every day before the start of the work day/shift, after every rainstorm and throughout the day as needed.

• Notify all other subcontractors on site and notify them of the excavation location.

• Ensure all vehicles and machinery are kept at a safe distance from the excavation.

Conclusion

Trench cave-in deaths, like the recent tragedy in Houston,

are avoidable through strict compliance with federal Occupational Safety and Health standards. The standards stress the need for a competent person to be in charge of all excavation and trenching activities at a job site. By following this critical advice and complying with the minimum requirements in federal standards, the majority of trench fatalities can be prevented.

Evan Gurley is a technical services engineer with NPCA.

1Visit www.chron.com/news/houston-texas/article/Worker-s-body-found-after-trench-collapse-2448357.php

2BLS [2010]. Census of fatal occupational injuries (2000−2009). Washington, D.C., Bureau of Labor Statistics. Deatherage JH, Furches LK, Radcliffe M, Schriver WR, Wagner JP [2004]. Neglecting safety precautions may lead to trenching fatalities. Am J Ind Med 45:522−527.

3Arboleda CA, Abraham DM [2004]. Fatalities in trenching operations analysis using models of accident causation. J Const Eng Mgmt 130(2):273−280.

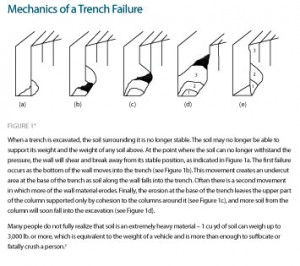

4Graphic abstracted from Mickle, 1991

OSHA Definitions

OSHA 29 CFR 1926 Subpart P concentrates on the industry minimum requirements and precautions that are enforced when performing excavations, addressing all open excavations made in the earth’s surface, including trenches, in order to protect workers who labor in trenches. Strict compliance with all sections of this standard will greatly reduce the risk of excavation-related accidents. Some common definitions and terms should be reviewed before addressing OSHA 29 CFR 1926 Subpart P requirements. OSHA 1926.650 defines the following terms:

Cave-in – the separation of a mass of soil or rock material from the side of an excavation, or the loss of soil from under a trench shield or support system, and its sudden movement into the excavation. This occurs either by falling or sliding, in sufficient quantity so that it could entrap, bury or otherwise injure and immobilize a person.

Competent Person – one who is capable of identifying existing and predictable hazards in the surroundings or working conditions that are unsanitary, hazardous or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them.

Protective system – method of protecting employees from cave-ins, from material that could fall or roll from an excavation face or into an excavation, or from collapse of adjacent structures. Protective systems include support systems, sloping and benching systems, shield systems, and other systems that provide the necessary protection.

Shield (Shield system) – a structure that is able to withstand the forces imposed on it by a cave-in and thereby protect employees within the structure. Shields can be permanent structures or can be designed to be portable and moved along as work progresses. Additionally, shields can be either pre-manufactured or job-built in accordance with OSHA 1926.652(c)(3) or (c)(4). Shields used in trenches are usually referred to as “trench boxes” or “trench shields.”

Sloping (Sloping system) – a method of protecting employees from cave-ins by excavating to form sides of an excavation that are inclined away from the excavation so as to prevent cave-ins. The angle of incline required to prevent cave-ins varies with such factors as the soil type, environmental conditions of exposure, and application of surcharge loads.

Trench (Trench excavation) – a narrow excavation (in relation to its length) made below the surface of the ground. In general, the depth is greater than the width, but the width of the trench (measured at the bottom) is not greater than 15 ft. If forms and other structures are installed or constructed in an excavation so as to reduce the dimension measured from the forms or structure to the side of the excavation to 15 ft or less (measured at the bottom of the excavation), the excavation is also considered to be a trench.

Leave a Reply